Features

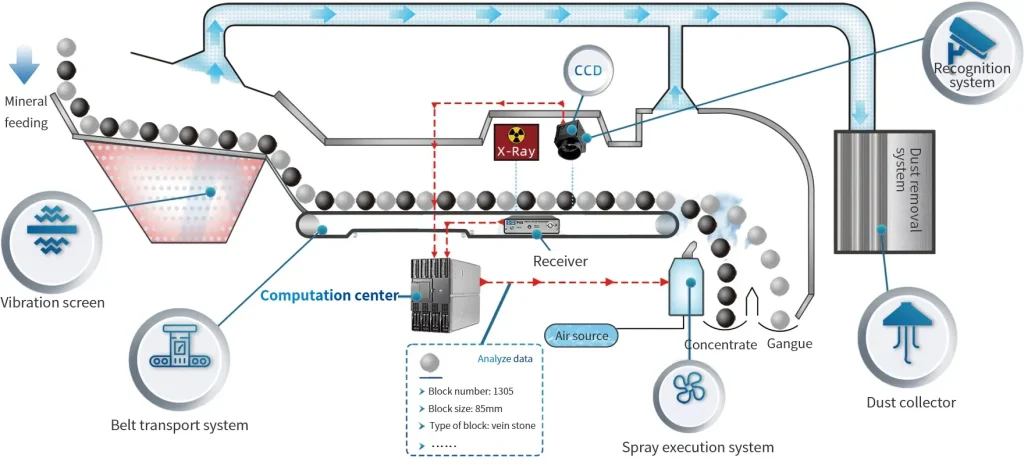

The use of a dual energy X-ray scanning imaging system to capture images of freely falling/sliding groove falling materials results in higher signal-to-noise ratio, wider particle size adaptability, and a lower limit of sorting particle size as low as 6mm.

- Cooperating with tens of thousands of customers, intelligent interconnection, and worry-free after-sales.

- Nearly a thousand process quality inspections, consistent quality, and excellence.

- Hundreds of algorithms have been developed to identify colors and shapes.

- Twenty years of deep cultivation in color sorting and doubled production.